Huawei Builds Complete Domestic AI Semiconductor Supply Chain

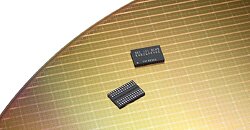

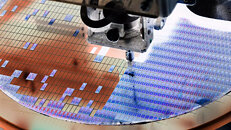

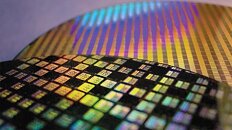

According to the Financial Times, gathering data from satellite images and industry intelligence, Huawei has endeavored to develop a domestic AI supply chain to bypass foreign tech restriction influence. In Guanlan, China, Huawei started developing a complete facility for manufacturing semiconductors on 7 nm technology for its custom processors. Out of frustration with SMIC's low output capacity, Huawei has secured the entire silicon production, from sourcing materials, chemicals, and wafer fab equipment to chip-making equipment to actual chip design. According to Dylan Patel of SemiAnalysis, "Huawei has embarked on an unprecedented effort to develop every part of the AI supply chain domestically from wafer fabrication equipment to model building," adding, "We have never seen one company attempt to do everything before."

It is also reported that Huawei's rivals in silicon manufacturing, SMIC and SMEE, have deployed engineers to help Huawei develop its own manufacturing flow. A few companies, all backed by Huawei with funding and research, are the backbone of this operation. SiCarrier, which we reported on back in March, supplies optical and X-ray inspection tools, atomic force microscopes, and alignment systems for metrology; gas-based and atomic layer deposition tools for film coating; plasma etchers for patterning; rapid thermal processors for material tuning; and electrical testing platforms for reliability screening. SwaySure and Fujian Jinhua supply memory chips, Si'En and Pehgjin supply power chips, and PWX and PST deal with logic.

It is also reported that Huawei's rivals in silicon manufacturing, SMIC and SMEE, have deployed engineers to help Huawei develop its own manufacturing flow. A few companies, all backed by Huawei with funding and research, are the backbone of this operation. SiCarrier, which we reported on back in March, supplies optical and X-ray inspection tools, atomic force microscopes, and alignment systems for metrology; gas-based and atomic layer deposition tools for film coating; plasma etchers for patterning; rapid thermal processors for material tuning; and electrical testing platforms for reliability screening. SwaySure and Fujian Jinhua supply memory chips, Si'En and Pehgjin supply power chips, and PWX and PST deal with logic.